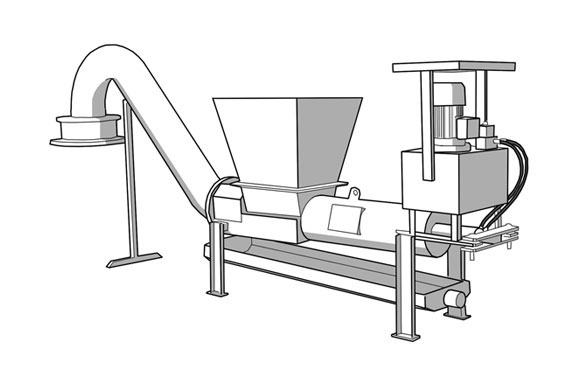

Hydraulic Conveying Press

Dehydrates, compacts, conveys the solid residues from filtration or screening of domestic and industrial wastewater. The screened material is collected by an hopper and fall into the compression chamber, an piston actuated by an hydraulic unit compresses and dehydrates the solids inside the cylinder which is perforated and allows the escape of leachate collected from a special tank.

Dehydration

The hydraulic conveying press separates the material that comes from screening machines and dehydrates it.

Compression

The volume of solids is drastically reduced up to 25% of the original volume, reducing costs of transport and disposal.Transport

The press conveys the material pressed up to the collection container through a closed pipe, which guarantees maximum hygiene. The tube can be applied with any angle. This transport and lifting function permits to avoid the purchase of a further transportation machine, like a belt o a screw.The size of the hopper, length and inclination of the pipe are adjusted depending on the requirements of the installation. All components are oversized to ensure strength and durability.

The press is made of AISI 304 stainless steel, including the hopper, the controller and the leachate collection tank.

At the end of the tube can be applied to a semi-automatic bagging system into a continuous bag LONGOPAC, which allows to transport to the place of storage in the maximum hygiene.

Each machine is marked and certified according to Machinery Directive 2006 42 CE

Gallery.

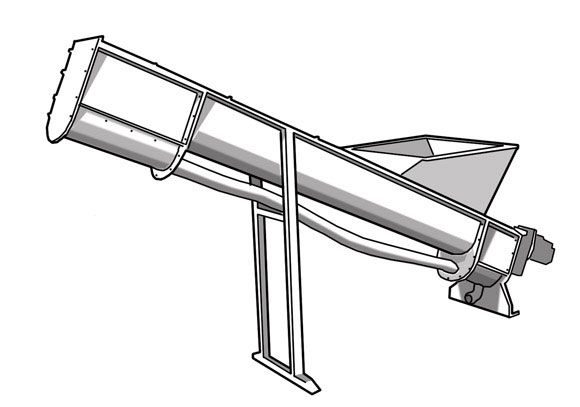

Screw compactor

Dehydrates, compacts, conveys the solid residues from filtration or screening of domestic and industrial wastewater. The screened material is collected by an hopper, where a shaftless screw, of appropriate thickness, which is directly keyed to the rotation gearbox, conveys the material through the conduit towards the dewatering and compacting zone. Once dewatered and compacted, the material comes out through the discharge mouth. The conduit is closed by a bolted cover, so as to allow a quick and easy maintenance.

Compression

The volume of solids is drastically reduced up to 50% of the original volume, reducing costs of transport and disposal.Transport

Opportunely sizing of the screw length, permits to combine the functions of transport and compaction of the material.The screw compactor is constructed of AISI 304 stainless steel, including the hopper. The screw is made ??of high resistance special steel.

The contact surface of the conduit consists of a series of interchangeable, wear-resistant, bolted plates.

At the end of the tube can be applied to a semi-automatic bagging system into a continuous bag LONGOPAC, which allows to transport to the place of storage in the maximum hygiene.

Each machine is marked and certified according to Machinery Directive 2006 42 CE

Italiano

Italiano English

English