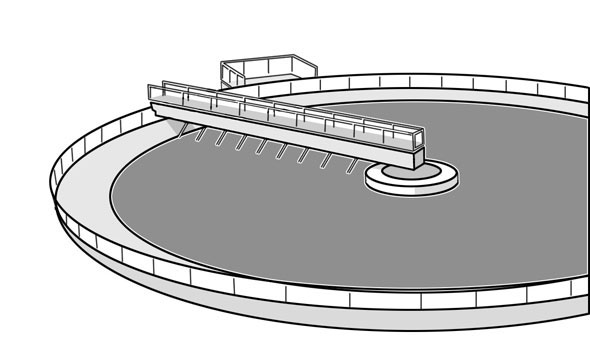

Peripheral scraper bridge

Peripheral scraper bridge is made to be installed in a circular basin of sedimentation and consists of a pivoting girder fixed at one end on the central column of the tank, and at the other end on a traction carriage.

The girder is made of cold bent thick steel and reinforced with welded sections.

Decking, railings and toeboards follow ISPESSL rules.

The central support is composed of a sturdy bearing mounted on a plate, support horizontal pin of the girder and the container of the collector for electricity distribution. Peripherl carriage is made of thick steel welded to the girder. It is complete with cast iron wheels with Wulkola rubber coating, supports with bearings and Italian maufactoring gearmotor.

The scraper blade is made of a series of vertical tubular supports anchored to the girder. At the ends there is a parabolic shape blade made of a steel part and a piece of rubber. The blade slide on the bottom of the tank because of rotating wheels with stainless steel supports.

The materials of construction, as needed, can be hot-dip galvanized carbon steel, AISI 304 or AISI 316 stainless steel.

Optionals

- Surface scum collection blade and "Scum box" tank.- Thompson weir plate and foam blocking blades.

- Central difuser drum anchored to the girder.

Gallery.

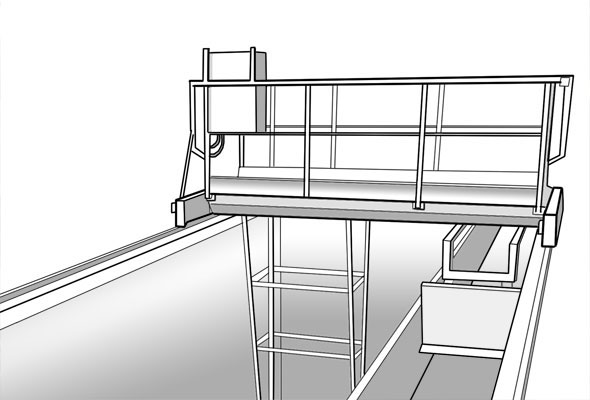

Travelling scraper bridge

Travelling scraper bridge is made to be installed in a rectangular tank. It is suitable to remove grit and oil.

Scrapers blades convey the material (mud, sand, etc..) on the bottom of the tank in a storage hopper, where they will be removed by pumps or air-lifts.

Similarly, scums and oils from the surface are conveyed by a special blade mounted on the deck to a hopper or scum box.

The materials of construction, as needed, can be hot-dip galvanized carbon steel, AISI 304 or AISI 316 stainless steel.

Gallery.

Italiano

Italiano English

English